Home

>

Products

>

Perforated Stainless Steel Sheet

>

Home

>

Products

>

Perforated Stainless Steel Sheet

>

201 304 316 bending food grade stainless steel perforated stainless steel

Here are some common parameters for 201, 304, and 316 stainless steel as well as perforated stainless steel sheets. Please note that these parameters may vary depending on the specific manufacturer and product.

| Parameter | 201 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | Perforated Stainless Steel Sheets |

|---|---|---|---|---|

| Chemical Composition | 17.5-19.5% Cr | 18-20% Cr | 16-18% Cr | - |

| 4-6% Ni | 8-10.5% Ni | 10-14% Ni | - | |

| 0.08% C | 0.08% C | 0.08% C | - | |

| 1% Mn | 2% Mn | 2% Mn | - | |

| 1% Si | 0.75% Si | 0.75% Si | - | |

| 0.045% P | 0.045% P | 0.045% P | - | |

| 0.03% S | 0.03% S | 0.03% S | - | |

| Physical Properties | ||||

| Density | 7.93 g/cm³ | 7.93 g/cm³ | 7.98 g/cm³ | - |

| Elastic Modulus | 200 GPa | 193 GPa | 193 GPa | - |

| Tensile Strength | 655 MPa | 515 MPa | 515 MPa | - |

| Yield Strength | 310 MPa | 205 MPa | 205 MPa | - |

| Hardness | HRB <95 | HRB <90 | HRB <90 | - |

| Corrosion Resistance | Good | Good | Excellent | - |

| Food-Grade Certification | Possibly compliant | Possibly compliant | Possibly compliant | - |

| Perforation Diameter and Layout | Customizable, as per requirements | |||

| Perforation Size and Shape | Customizable, as per requirements | |||

| Sheet Thickness | Customizable, as per requirements | |||

Food-grade certification: 201, 304, and 316 stainless steel materials typically meet food-grade certification standards such as FDA (U.S. Food and Drug Administration) and EU (European Union) food contact material certification. This means they are recognized as suitable for direct contact with food, posing no harm to food quality and safety.

Hygiene performance: Stainless steel is a non-reactive material that does not undergo chemical reactions with food components. It has a smooth surface that is resistant to bacterial adhesion and dirt accumulation, making it easy to clean and sanitize. This makes stainless steel an ideal choice for the food processing industry, contributing to the maintenance of food hygiene and safety.

Corrosion resistance: 201, 304, and 316 stainless steel all possess excellent corrosion resistance. They can withstand acidic and alkaline components in food, as well as the corrosive effects of humidity and moisture. This enables stainless steel to be used in humid and corrosive environments for prolonged periods while maintaining its strength and appearance.

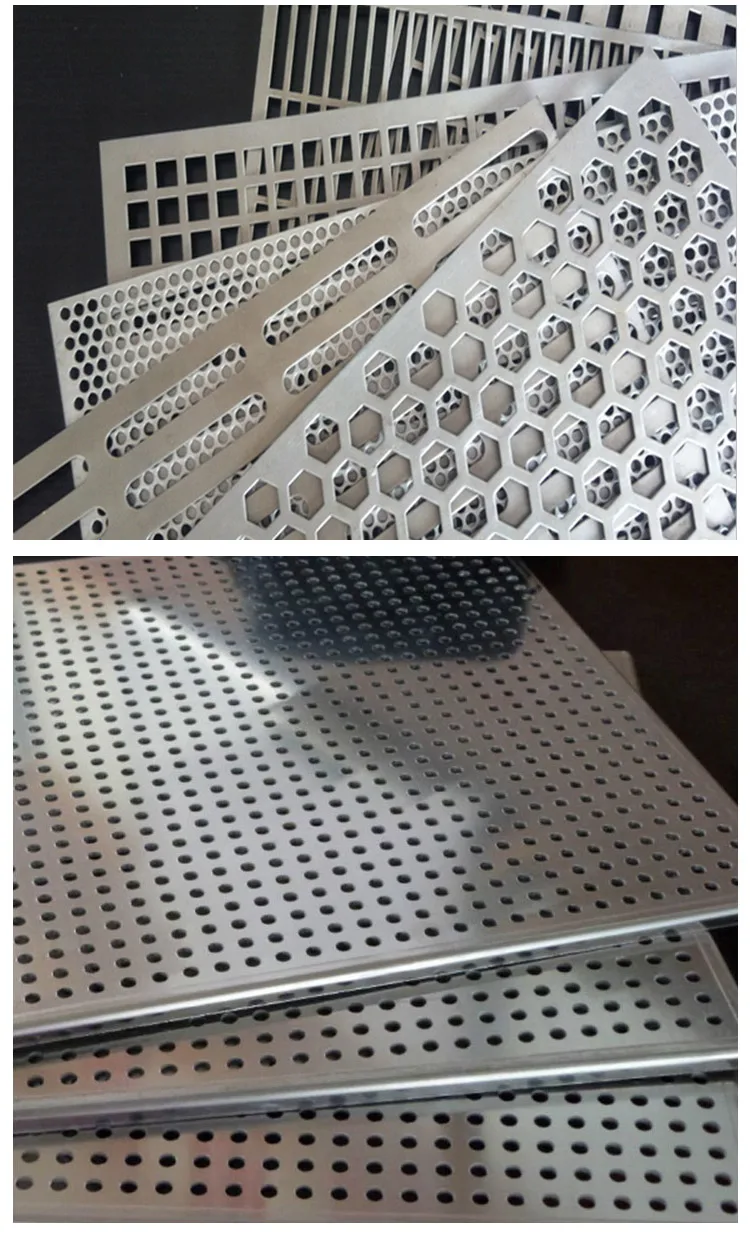

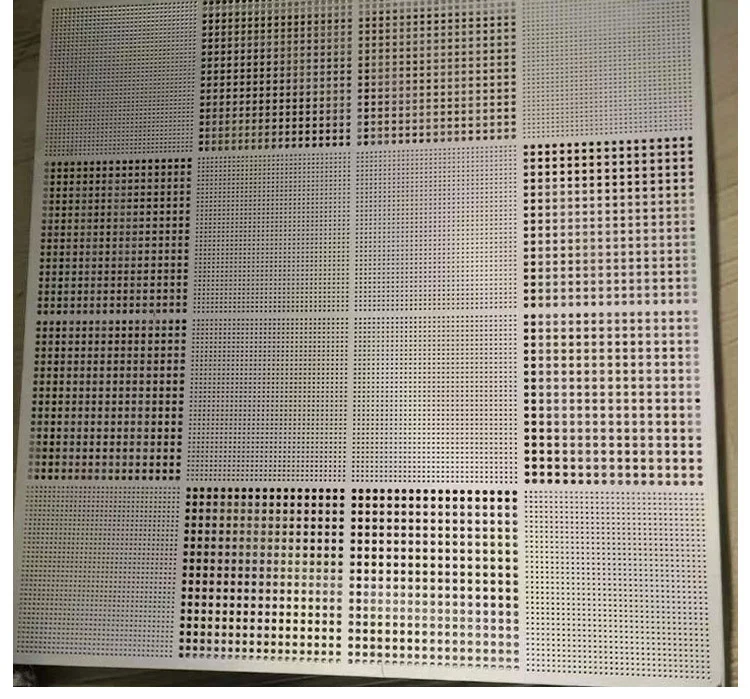

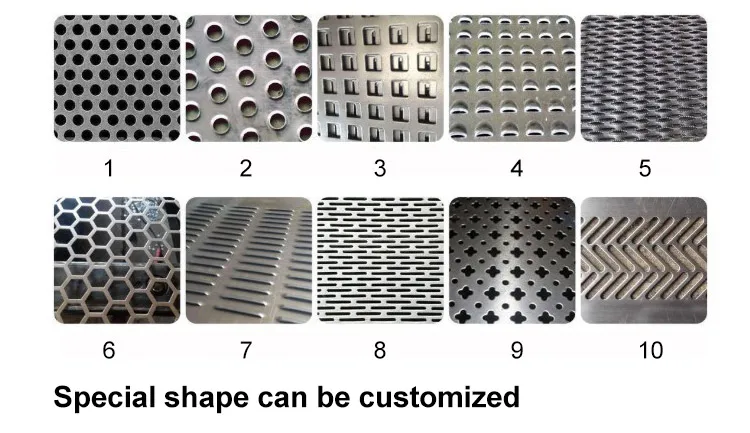

Perforation design: Perforated stainless steel sheets can be customized according to specific design requirements. The hole size, shape, and layout can be adjusted as needed to achieve specific screening, filtering, or ventilation effects. This flexibility allows perforated stainless steel sheets to meet the requirements of various applications and provide customized solutions.

Strength and durability: Stainless steel exhibits exceptional strength and durability, enabling it to withstand physical pressure and stress during food processing. It maintains stability in shape and structure, resisting deformation or breakage and providing reliable performance and a long lifespan.

Overall, food-grade stainless steel and perforated stainless steel sheets play a crucial role in the food processing industry. They offer safe, hygienic, corrosion-resistant, and customizable solutions for various applications such as food processing equipment, storage containers, screening, and filtering systems.

Perforated metal mesh means metal sheets has all kinds holes its surface.It is perforated by various of materials of steel plate,also called perforated metal mesh and steel perforated metal mesh.Punching sheet steel by a variety of materials made by the CNC punch press stamping,punching network also often referred to as punching with steel punching mesh network.

Round hole perforated sheets are the most common and most requested.There are several types of hole diameters:very small,medium,large size.Hole pattern is of primary importance:the most popular arrangement is the 60 degree angle pattern,which combines a high rigidity and a decent proportion between open and full areas.The 90 degree pattern is equally popular,abouve all for aesthetic needs whereas the 45 degree pattern is now almost disused.

Contact Us at Any Time