ASME 201 304 Hot Rolled Stainless Steel Coil 0.28-3mm Thickness

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | Grand Metal |

| Certification: | ISO9001 |

| Model Number: | 201 304 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20 Tons |

|---|---|

| Price: | $1,750.00/Tons 20-49 Tons |

| Packaging Details: | Packaging: According to customers' needs, use wrapping paper. If the transportation period exceeds 10 days or encounters special climate, we will use waterproof packaging and add plastic film to prevent moisture, water and rust.<br><br>Loading: We use the |

| Delivery Time: | 7-15work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000000 Ton/Tons per Month |

|

Detail Information |

|||

| Application: | ASTM 201 304 Hot Rolled Stainless Steel Coil | Grade: | 200/300 Series |

|---|---|---|---|

| Thickness: | 0.28-3mm | Width: | 30-1240mm |

| Tolerance: | ±5% | Processing Service: | Welding, Punching, Cutting, Bending, Decoiling |

| Steel Grade: | 201 304 | Color: | Natural Color |

| Technique: | Cold Rolled | Type: | Coil |

| High Light: | ASME Hot Rolled Stainless Steel Coil,0.28mm Hot Rolled Stainless Steel Coil,3mm 201 stainless steel coil |

||

Product Description

ASTM 201 304 Hot Rolled No 1 Stainless Steel Coil for kitchenware

1.product description

| Description | ASTM 201 304 Hot Rolled No 1 Stainless Steel Coil for kitchenware |

| Standard | ASTM GB/T JIS4 ASME BS DIN EN. |

| Material | 310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, |

| 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex, etc | |

| Brand name | Grand Metal |

| Technique | Hot Rolled And Cold Rolled. |

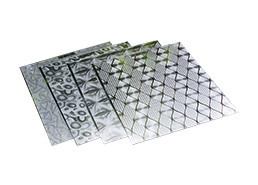

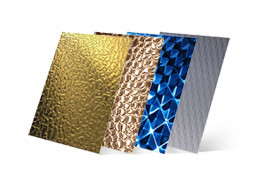

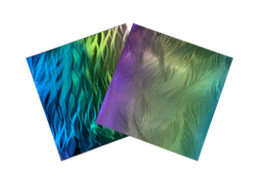

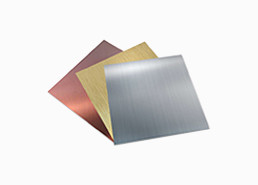

| Surface | 2B, 2D, BA, NO. 1, NO. 4, NO. 8, 8K, mirror , checkered , embossed , hair line, sand blast,Brush, etching, etc |

| Thickness | 0.25~150mm |

| Width | 600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Price term | Ex-Work, FOB, CNF, CFR, CIF, etc |

2.surface information

| Surface finish | Characteristics and application |

| NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface |

| treatment to improve its mechanical properties,No2B could nearly satisfy | |

| comprehensive uses. | |

| The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling. | |

| NO.1 | |

| NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous |

| coarse stria,but thinner than No3, are used as bathtub buildings inner and external | |

| ornaments electrical appliances kitchen utensils and food processing equipment etc. | |

| Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streak | |

| HL | mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good |

| reflexivity like mirror,kitchen apparatus,ornament etc. | |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Hot rolled stainless steel coil

· Size: 1000mm-2200mm

· W.T: 3-20mm

· Surfaces: No.1

· Grade: 201/202/301/304/304L, etc

· Product description: HST Stainless steel manufactures and supplies high quality of stainless steel hot rolled coils with variety sizes and grades in China. Contact for the reasonable prices in China!

· Hot rolled stainless steel coil - HST hot rolled Stainless steel coil is available in a variety of stainless steel grades, dimensions and Surfaces, with a wide range of finishing actions provided by our service centers in appropriate prices.

· Our Company supplies stainless steel coils of various grades in accordance with ASTM/AISI standards.

· Normally thickness and width tolerances of regular Stainless steel strips and coils are regulated by the standard ASTM

· HST hot rolled stainless steel coils are a very popular choice for applications from consumer goods and prestigious buildings to corrosion resistant solutions for the process industry. Hot-rolled coil and sheet are used in applications such as the production of process plant equipment and a host of other applications.

It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture,ship components.

It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs,and screen.

|

- Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade, etc.

- For furniture, kitchenware, food industry, electronic industry, medical equipment, etc. |

Stainless steel coil packaging and loading

Packaging: According to customers' needs, use wrapping paper. If the transportation period exceeds 10 days or encounters special climate, we will use waterproof packaging and add plastic film to prevent moisture, water and rust.

Loading: We use the wooden pallet,triangular wood to fix the coil,and the steel wire rope to hold on the both side. That can prevent from the crush injury effectively.

![]()

Q1.About us,the relation between factory,manufacture or trader?

A1. Grand Metal group is a professional production of coldrolled stainless steel conglomerate , with professional production of stainless steel experience and our own factory nearly 12 years,where has more than 1,000 professional and technical workers. we are the foreign trade department of Grand Metal. All our goods are dispatched directly from Grand Metal mill.

Q2.What are Grand Metal’s main products?

A2.Grand Metal’s main products include 201/304 stainless steel coil and sheets,all different styles of etched and embossed,surface finished will be customized.

Q3.How can you ensure the quality of your product?

A3.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Q4.What is your delivery time and the supply ability?

A4.The delivery time normally within 15~20working days,we can supply about 15,000tons every month.

Q5.What kind of equipment in your factory?

A5.Our factory have advanced five-eighth roller rolling,cold rolling production equipment on the roll,advanced processing and testing equipment,which makes our product better quality with efficiency.

Q6.About the complaint,quality problem,etc aftersales service,how do you handle it?

A6.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

Q7.As the first customer,how do we trust you?

A7.On the top of page,you can see a line of credit with $228,000. It provides our company with higher degrees of credibility in the alibaba.We can guarantee the safety of your order.